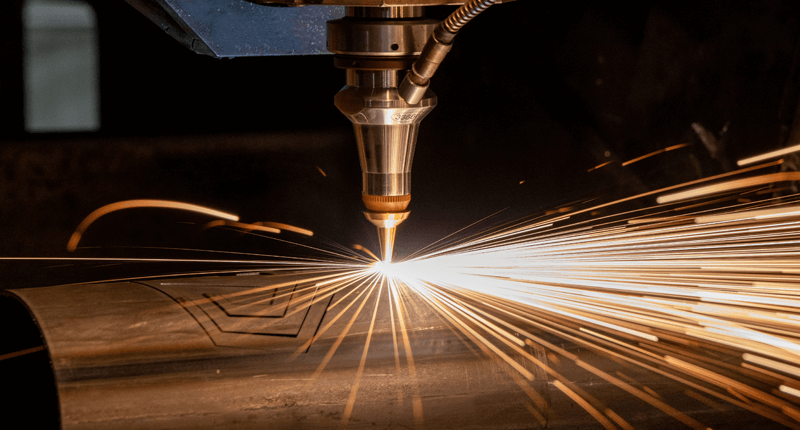

In today’s fast-paced industries, precision and efficiency are not just advantages; they are necessities. CNC tube laser cutting has emerged as a transformative technology, offering unmatched accuracy and versatility for a wide range of applications. At Cutting Edge Steel, we pride ourselves on harnessing this technology to deliver solutions that elevate projects from good to exceptional.

What is CNC Tube Laser Cutting?

CNC tube laser cutting is an advanced method for cutting and shaping tubular materials with remarkable precision. The process combines laser cutting technology with CNC automation to produce highly accurate and intricate cuts on tubes, pipes, and profiles. This approach eliminates the guesswork of traditional methods and ensures every cut is flawless, repeatable, and ready for assembly.

Whether you need custom cuts for furniture, automotive components, or architectural designs, CNC tube laser cutting is the answer to achieving exceptional results.

Advantages of CNC Tube Laser Cutting

What sets CNC tube laser cutting apart from other fabrication methods? Let’s explore some key benefits:

1. Precision and Accuracy: The CNC-controlled laser ensures that every cut meets exact specifications, down to fractions of a millimeter. This level of precision is essential for industries like aerospace, automotive, and construction, where accuracy is non-negotiable.

2. Versatility: Our CNC tube laser cutter can handle a variety of materials, including steel, aluminum, and more. It’s also equipped to cut complex geometries, openings, and contours with ease, making it perfect for custom projects.

3. Cost-Effective Production: By minimizing material waste and reducing the need for secondary operations, CNC tube laser cutting streamlines production and lowers overall costs. This is especially beneficial for large-scale projects.

4. Speed and Efficiency: CNC automation accelerates the cutting process without sacrificing quality. Quick turnaround times mean your project stays on schedule and within budget.

5. Clean, High-Quality Cuts: Laser cutting produces smooth edges and eliminates the need for deburring, saving time and ensuring your parts are assembly-ready right off the machine.

How Cutting Edge Steel Stands Out

At Cutting Edge Steel, we don’t just offer CNC tube laser cutting services—we deliver a partnership built on quality, innovation, and reliability. Here’s what makes us different:

- State-of-the-Art Technology: Our advanced CNC tube laser cutter ensures precision and efficiency for even the most complex projects.

- Experienced Team: With years of expertise in fabrication, we collaborate closely with clients to understand their needs and exceed expectations.

- Commitment to Sustainability: Our cutting process minimizes material waste, helping your project align with eco-friendly practices.

Applications of CNC Tube Laser Cutting

From industrial to creative projects, the possibilities are endless with CNC tube laser cutting. Some common applications include:

- Automotive: Custom components for vehicles, including exhaust systems and chassis parts.

- Furniture: Modern designs with clean, precise cuts for tables, chairs, and more.

- Architecture: Intricate patterns and structural elements that blend functionality with aesthetic appeal.

- Manufacturing: High-precision parts for machinery and equipment.

Ready to Transform Your Next Project?

When it comes to CNC tube laser cutting, Cutting Edge Steel is your trusted partner for precision, speed, and reliability. Whether you’re tackling a large-scale industrial project or crafting intricate custom designs, we have the expertise and technology to bring your vision to life.

Contact us today to learn more about how our CNC tube laser cutting services can elevate your project to the next level. Let’s create something extraordinary together!